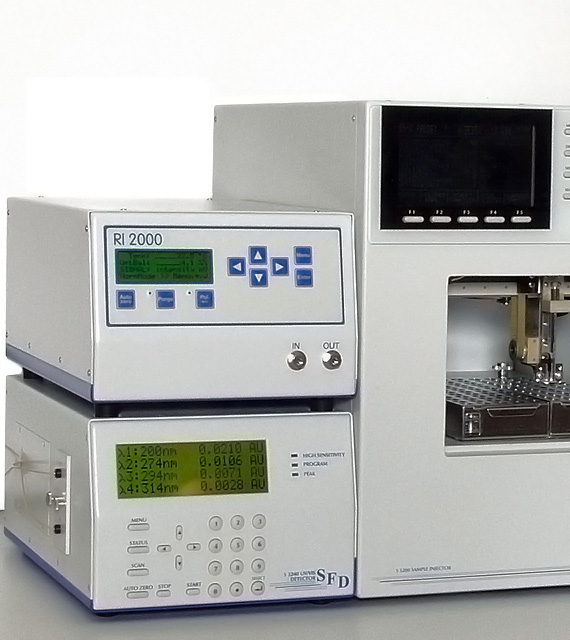

GC-Autosampler

HT200H 40-Vial Headspace Autosampler

- Interfaces with SRI and other GCs

- Holds 40 Standard 20mL Headspace Vials

- Injects directly into the GC – no transfer lines

- 6 Position Incubator with Orbital Shaking

- Progressive Sample Transfer

The HT200H Headspace Autosampler is designed to meet the requirements of static headspace injection for GC analysis. The swivel head design simulates the movements of manual direct injection and eliminates the need for transfer lines.

The injection tower smoothly transports the vials to

the six position incubator, where they are orbitally agitated at the

user-programmed temperature. The heated syringe then samples the

headspace and injects directly into the GC. The 2.5 or 5mL syringe is

purged with inert gas after injection. The incubator oven and the

heated syringe have the same programmable temperature range of 4-150oC.

The rotating design leaves the injection port available for manual

injections at any time. The HT200H processes samples so that headspace

injections start immediately after the previous run is completed.

Up to 10 analytical methods, including all the user-selected options listed in the OPERATING SPECIFICATIONS table, may be stored in the HT200H memory.

Up to 10 analytical methods, including all the user-selected options listed in the OPERATING SPECIFICATIONS table, may be stored in the HT200H memory.

The HT200H picks up the vial ...

... and places it in the incubator.

Operating Specifications

Product number:

8690-3000 110-Vial Liquid Autosampler

| Sampling |

|

| Sample volume |

steps of 0.1uL |

| Air volume |

steps of 0.1uL |

| Aspirating speed |

0.1uL - 100uL/second |

| Needle washing |

up to 15 |

| Air bubble removal |

up to 15 strokes |

| Viscosity time |

1 - 60 seconds |

| Syringe sizes |

1, 10, 25, 50, 100uL (1000uL large volume version) |

| Injection |

|

| Injection speed |

0.1uL - 100uL/second |

| Waiting time before & after injection |

1 - 60 seconds |

| Injection depth |

variable |

Product number:

8690-3000 110-Vial Liquid Autosampler

HT280T Headspace, Liquid and SPME Autosampler

The HT280T is a single unit combining static headspace analysis, liquid sample injection and SPME (Solid Phase Microextraction)!

As the successor to the hugely popular HT250D, the HT280T effectively combines the operations of the HT200H Headspace Autosampler and the HT300A Liquid Autosampler, with the addition of SPME.

Consider that the HT280T is compatible with almost all GC and GC/MS systems, both present and past, and you have a truly remarkable development in GC autosampling.

The HT280T can save you time and money, increase analysis flexibility and save older GCs from redundancy. Changing between liquid, headspace and SPME modes is very simple. It takes about 5 minutes and there's no need to remove the sampler from the GC.

As the successor to the hugely popular HT250D, the HT280T effectively combines the operations of the HT200H Headspace Autosampler and the HT300A Liquid Autosampler, with the addition of SPME.

Consider that the HT280T is compatible with almost all GC and GC/MS systems, both present and past, and you have a truly remarkable development in GC autosampling.

The HT280T can save you time and money, increase analysis flexibility and save older GCs from redundancy. Changing between liquid, headspace and SPME modes is very simple. It takes about 5 minutes and there's no need to remove the sampler from the GC.

Headspace Operation

The system is uses a heated syringe to extract headspace samples from the 6 position orbital oven/shaker. This eliminates tubing, dead volume and sample absorption. Vial transport is positive and incredibly reliable – the system constantly checks that vials are present and are located in the correct place. No expensive magnetic caps are required. No transfer lines are required and the unit mounts directly on the GC thus reducing bench space requirements.

Operation is via the simple keypad or by HT-COMSoft software. Up to 40 headspace vials of 20ml or 10ml may be stored in the standard tray. Progressive sample preparation means that samples are automatically loaded into the oven at the correct time to ensure an injection is ready as soon as the previous run is complete, maximizing your GC efficiency.

Key Features:

Liquid Sampler Operation

Up to 110 samples may be processed as single or batch injections using one or more analysis methods. Any 12x32mm vial may be used with any cap type. All parameters from the sampling depth through to the injection speed, depth and dwell times may be programmed through the front panel or via the HT-COMSoft software

The automatic injection sequence may have up to 15 steps which can be programmed to include:

Key Features:

The system is uses a heated syringe to extract headspace samples from the 6 position orbital oven/shaker. This eliminates tubing, dead volume and sample absorption. Vial transport is positive and incredibly reliable – the system constantly checks that vials are present and are located in the correct place. No expensive magnetic caps are required. No transfer lines are required and the unit mounts directly on the GC thus reducing bench space requirements.

Operation is via the simple keypad or by HT-COMSoft software. Up to 40 headspace vials of 20ml or 10ml may be stored in the standard tray. Progressive sample preparation means that samples are automatically loaded into the oven at the correct time to ensure an injection is ready as soon as the previous run is complete, maximizing your GC efficiency.

Key Features:

- No transfer lines means no sample crossover

- Rotating head design leaves injection port free for manual injection

- Progressive sample transfer means samples always ready when previous run completed

- May be configured for left or right operation

- Gas flush of syringe between injections

Liquid Sampler Operation

Up to 110 samples may be processed as single or batch injections using one or more analysis methods. Any 12x32mm vial may be used with any cap type. All parameters from the sampling depth through to the injection speed, depth and dwell times may be programmed through the front panel or via the HT-COMSoft software

The automatic injection sequence may have up to 15 steps which can be programmed to include:

- First and last samples of group

- Injection method

- Number of injections for each sample

- Pre- and Post-washing solvent position

- Internal Standard (if used)

Key Features:

- No transfer lines means no sample crossover

- Syringe may be washed with solvent or sample

- Injections may be made on two columns (high throughput and confirmation mode)

- Rotating head design leaves injection port free for manual injection

- Internal standard sampling

- Memory stores 10 different methods

- Variable fill speed allows for wide range of sample viscosities

- Sampling system eliminates air bubbles

- Programmable sampling and injection speed

SPME Operation

SPME is a unique sample preparation technique that eliminates most of the drawbacks associated with extracting organics. SPME requires no solvents or complicated apparatus.

SPME has gained widespread acceptance as the technique of preference for many applications including: flavours, fragrances and contaminants in food; forensic and toxicology applications; environmental and biological matrices; organic volatiles in pharmaceutical compounds. Automated SPME with the HT280T delivers more accurate results with greater throughput than manual SPME.

SPME is a unique sample preparation technique that eliminates most of the drawbacks associated with extracting organics. SPME requires no solvents or complicated apparatus.

SPME has gained widespread acceptance as the technique of preference for many applications including: flavours, fragrances and contaminants in food; forensic and toxicology applications; environmental and biological matrices; organic volatiles in pharmaceutical compounds. Automated SPME with the HT280T delivers more accurate results with greater throughput than manual SPME.

The HT280T can extract volatile and non-volatile compounds in both liquid and headspace samples using

variable vial penetration depth. Samples can be derivatised pre or post-extraction as the application requires.

The extraction is performed by exposing the fibre into the sample vial. Samples can be agitated by orbital rotation

and heated during extraction.

Both the shaking speed and oven temperature are programmable. The oven door is kept closed during extraction to maintain constant temperature. After the compounds have been thermally desorbed in the GC injector, the fibre may be fully cleaned again in the optional heated fibre cleaning station positioned at the back of the unit. Key Features:

Both the shaking speed and oven temperature are programmable. The oven door is kept closed during extraction to maintain constant temperature. After the compounds have been thermally desorbed in the GC injector, the fibre may be fully cleaned again in the optional heated fibre cleaning station positioned at the back of the unit. Key Features:

- Single step extraction (reduces sample preparation time by up to 70%)

- Minimal use of solvents

- Programmable extraction depth to perform both headspace and liquid extraction

- Oven door kept closed during extraction to keep temperature constant

| Specifications | |

| Data System Compatibility: | EZChrom Elite and DataApex Clarity (Headspace and liquid modes only) |

| HEADSPACE OPERATION | |

| Shaking Method: | Orbital |

| Incubation Oven: | 6 position |

| Syringe Size: | 2.5ml |

| Tray Capacity: | 40 Vials, 10 or 20ml |

| Cleaning System: | Nitrogen flush |

| Conditioning | |

| Oven Temperature: | 40 - 150°C |

| Time: | 0 - 23h 59m |

| Progressive Increase: | 0 - 9h 59m |

| Shaker Speed: | 320 - 720rpm |

| Shaking Cycles On/Off: | 0 - 9.9mins |

| Sampling | |

| Syringe Temperature: | 40 - 150°C |

| Pre-fill Volume: | Steps of 0.01ml |

| Pull Up Strokes: | Up to 15 Strokes |

| Equilibrium Delay: | Up to 60secs |

| Sampling Volume: | Steps of 0.01ml |

| Filling Speed: | 0.1 - 100ml/min |

| Injection | |

| Sampling Repeats: | Up to 15 |

| Waiting Time between Samples: | 0 - 99mins |

| Injection Speed: | 0.1 - 100ml/min |

| Waiting Time (before and after injection): |

0 - 99secs |

| LIQUID OPERATION | |

| Syringe Sizes: | 1, 10, 25, 50 & 100μl |

| Tray Capacity: | 110 Vials, 2 or 2.5ml |

| Sample Volume: | Steps of 0.1μl |

| Air Volume: | Steps of 0.1μl |

| Aspirating Speed: | 1 - 100μl/sec |

| Needle Washing: | Up to 15 Strokes |

| Washing Mode: | Every injection, sample or step |

| Air Bubble Removing: | Up to 15 Strokes |

| Viscosity Time: | 0 - 15secs |

| Injection | |

| Injection Speed: | 0.1 - 100μl/sec |

| Waiting Time (before and after injection): |

0 - 99secs |

| Injection Depth: | Variable |

| Internal Standard Technique | |

| IS Volume: | Steps of 0.1μl |

| Air Gap Volume: | Steps of 0.1μl |

| Mode: | 1 or 2 air gaps |

| SPME OPERATION | |

| Extraction: | Liquid and Headspace |

| Tray Capacity: | 40 Vials, 10 or 20ml |

| Extraction Depth: | Variable |

| Shaking Method: | Orbital |

| Incubation Oven: | 6 position |

| Oven Temperature: | 40 - 150μC |

| Shaker Speed: | 320 - 720rpm |

| Oven Door: | Kept closed during extraction |

| Fibre Cleaning Station (optional): |

Variable duration |

| GENERAL | |

| Control | |

| Electrical Control: | RS232 and TTL |

| Physical Characteristics | |

| Dimensions (W x H x D): | 420 x 620 x 400mm |

| Mass: | 11.5kg |

HT300A 110-Vial Liquid Autosampler

- Holds 110 2mL or 2.5mL vials

- Interfaces with SRI and other GCs

- 15-Step Automatic Injection Sequence

- Direct Injection, No Transfer Lines

The HT300A Liquid Autosampler is made to meet the high throughput liquid injection needs of your GC analysis. Like the HT200H Headspace Autosampler, the swivel head design simulates the movements of manual direct injection and eliminates the need for transfer lines, as well as leaving the injection port free for manual injections. Up to 10 analytical methods, including function speeds, may be stored in the HT300A's memory.

The automatic injection sequence may have up to 15 steps, which may be programmed to include:

- First sample of group

- Last sample of group

- Analytical method

- Number of injections for each sample

- Pre and post washing solvent position

- Internal standard position (if used)

The sampling system eliminates air bubbles, and the variable fill speed allows for a wide range of sample viscosities. The syringe may be washed with solvent or sample.

Operating Specifications

Product number:

8690-3000 110-Vial Liquid Autosampler

| Sampling |

|

| Sample volume |

steps of 0.1uL |

| Air volume |

steps of 0.1uL |

| Aspirating speed |

0.1uL - 100uL/second |

| Needle washing |

up to 15 |

| Air bubble removal |

up to 15 strokes |

| Viscosity time |

1 - 60 seconds |

| Syringe sizes |

1, 10, 25, 50, 100uL (1000uL large volume version) |

| Injection |

|

| Injection speed |

0.1uL - 100uL/second |

| Waiting time before & after injection |

1 - 60 seconds |

| Injection depth |

variable |

Product number:

8690-3000 110-Vial Liquid Autosampler

_115.jpg)

_115.jpg)

_115.jpg)